DIGITAL FABLAB

Modernisation of the footwear industry thanks to CAD tools

In order to know how CAD/CAM has modernised the footwear industry, it is important to first understand what it is. The use of computers and graphics programmes for designing and realising the sizing of shoe patterns, the design and subsequent production of cutting dies, the planning of shoe cutting material, last moulds and soles, is known as Computer Aided Design and in its abbreviated form as CAD. These tasks can be tackled from 2D and 3D perspectives. CAD software can be found in both Operating Systems Windows and Linux versions, and in both free versions, as well as many others advanced paid commercial suites.

Some history is needed before we look at how CAD has changed the footwear industry. Automated design was introduced into the industry in the 1970s. At first, it was mainly used for pattern grading. It allowed manufacturers to carry out complex grading relatively easily and quickly. Today, CAD systems have developed with a much wider range of functions. Textures can be incorporated, materials can be tested, decorations can be added to pattern cuts. We can design soles and simulate them before they go into production to see how they perform. Routine procedures are automated, which increases speed and consistency between designs and reduces the possibility of errors. CAD/CAM generates much richer data at the design stage, which can be used in the planning and manufacturing stages.

CAD/CAM software can:

- Create a shoe last using a 3D scanner.

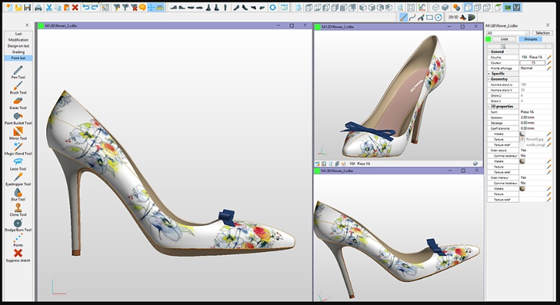

- Create virtual 3D footwear designs and produce renderings of these to enrich our collections.

- Create pattern data in 2D. (some software can display it from 3D).

- Facilitate the creation of the sizing of a collection.

- Create manufacturing documentation, manufacturing orders, work parts.

Obtain analytical cost information for the designed parts.

- These systems have progressively become much more intuitive and easier to use.

- With the 2D sketching and painting modules, a complete first design can be made, and even colouring and texturing can be added.

With CAD/CAM software, footwear manufacturers can drastically reduce their time to market and, thus, increase their market share and profitability. In addition, the power and flexibility of the software can unleash the creativity of the designer that traditional methods cannot. Let's discover how CAD has changed the footwear industry:

Design of the upper pattern.

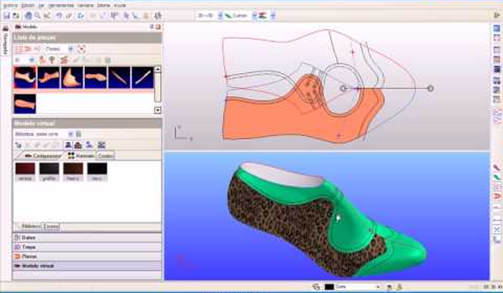

Using a 2D CAD module, the pattern lines can be created and designed with the help of a digitalising tablet or a mouse. The designer can create as many upper patterns as he wants in an agile on the screen of his device using a series of special functions perfectly adapted to his work in all its phases. These patterns can also be corrected and combined with already designed parts. CAD tools of this type allow distances, lengths, and areas, etc., to be measured with great precision and ease. For example, the use of a 3D CAD module allows to obtain a three-dimensional representation of the shoe upper through the geometric data of the upper obtained from an optical scanner or a stylus. Once this representation has been obtained, the upper can be projected onto the image of a virtual last on the monitor. This module can also display the 3D parts in 2D for later use.

For example, the use of a 3D CAD module allows to obtain a three-dimensional representation of the shoe upper through the geometric data of the upper obtained from an optical scanner or a stylus. Once this representation has been obtained, the upper can be projected onto the image of a virtual last on the monitor. This module can also display the 3D parts in 2D for later use.Patterns are a very important source of information in footwear design, as they are used to generate the upper dies, and their templates/patterns can be generated on a CAD workstation. Most systems can import and export various graphic data formats that allow their subsequent computation by other CAD systems or database programmes.

Sizing and grading of patterns

Die manufacturing

Automated leather upper cutting

Cost calculation

Footwear last design

Lasts can now be produced on a selection of CNC lathes and milling machines using data obtained from footwear manufacturers' CAD systems. Last shapes can be modified, and new lasts can be created in CAD systems and machining can be controlled using their data. Variations for example in the shape of the toe cap, the curve of the heel, etc. can easily be produced. Combining parts from different lasts can also be done in a few moments with CAD technology. It is also possible to develop the design and tooling of the shoe before the last physically exists, as they are all derived from the same source data in the CAD system.

Lasts can now be produced on a selection of CNC lathes and milling machines using data obtained from footwear manufacturers' CAD systems. Last shapes can be modified, and new lasts can be created in CAD systems and machining can be controlled using their data. Variations for example in the shape of the toe cap, the curve of the heel, etc. can easily be produced. Combining parts from different lasts can also be done in a few moments with CAD technology. It is also possible to develop the design and tooling of the shoe before the last physically exists, as they are all derived from the same source data in the CAD system.Unique design and small series

The CAD/CAM software can be used to generate unique mould machining data for small runs, which shoe mould makers can produce in a more flexible way in order to meet the fast-changing market demands. CAD systems also promote quality improvement and increase the versatility of the entire production chain. For example, the software helps sports shoe manufacturers produce shoes quickly and introduce them before their competitors.By CTCR